How Is Drywall Made?

How Is Drywall Made?

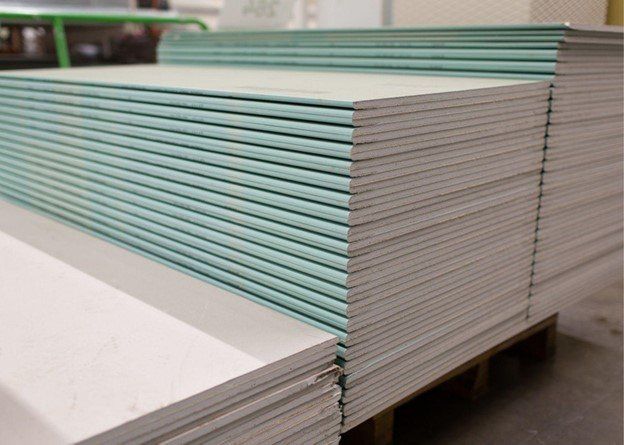

Drywall is one of the most common building materials in use today. While most of us live and work with drywall all around us, few of us know much about it. What exactly is drywall, and how is it made?

A mineral known as gypsum is the main ingredient in drywall. Though it is nearly 50% water, the water remains in a dry, crystalline form until it is heated past 100°C (which is the main reason that drywall is fire resistant). While you may not be familiar with gypsum by name, it is a component of many of the products you use every day. In addition to providing the core of drywall, gypsum is used as an ingredient in many toothpastes, an additive in bread (to increase the calcium content), a fertilizer, and a filler ingredient in cosmetics and paints.

The other important ingredient in drywall is paper. Paper forms the outside layers of a sheet of drywall, giving the gypsum a smooth and paintable outer surface. Much of the paper used for drywall today is made from recycled newspaper. For specialty types of drywall, additives are added to the paper to make it mold resistant, moisture resistant, or easier to plaster or paint.

Despite its many uses, the millions of tons of gypsum that are mined in North America each year are largely used to manufacture drywall. To create the inner layers of drywall sheets, gypsum is pulverized and mixed with water, starch, paper pulp, and other special additives to give certain drywalls certain properties. This mixture is then poured between two sheets of paper as they move through a special machine on a conveyor belt.

As the paper and gypsum mixture move through the machine, rollers compress the gypsum to the desired thickness. The machine then creates the desired edge on the sheets and wraps the front paper around to the back, sealing the gypsum mixture inside. Once the gypsum has solidified enough, the drywall is cut into sheets of the desired length.

Finally, the cut sheets of drywall pass through a drying oven. This oven starts out extremely hot and gradually decreases its temperature during the 35 to 45 minute drying process. Once dry and cool, the drywall is ready to be shipped out and

installed!

Over the years, the process of manufacturing drywall has improved and expanded. Drywall weighs less than it did fifty years ago, and specialty types of drywall are constantly being developed and improved to increase the performance and durability of the material. As long as drywall continues to be widely used, it will continue to be improved!

Drywall is made from some of the most widely used materials in our society today. Through a precise manufacturing process, it is transformed into one of the most recognizable building materials in use. Gypsum has been used to cover walls for thousands of years, and it isn’t going out of style any time soon!

Still have questions?

Our professionals are here to help with all your drywall needs!

You might also like